plastic impact tests|types of impact testing : agent Types of Plastics Impact Testers. The two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused . Harry Potter e o Enigma do Príncipe. 7.6 153 min. À medida que Lorde Voldemort aperta seu cerco ao mundo dos Trouxas e dos feiticeiros. Hogwarts deixou de ser um paraiso protegido. Harry suspeita que existam perigos até mesmo dentro do castelo, mas Dumbledore está mais preocupado para a batalha final que está próximo de se iniciar.

{plog:ftitle_list}

WEBSail on the sea-furrowing ships and explore the mossy ruins of Aztek temples with arresting slot games. Behold the ever-changing dance of kings and queens and numbers with BoaBoa’s card games. Try not to fall in trance when you follow the spinning of roulette wheels. Decide which live casino dealer looks the most professional.

Types of Plastics Impact Testers. The two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused .Impact testing is a critical step in ensuring the safety of plastic products. This article explains the importance of impact testing and how to perform it.The ASTM D256 standard describes impact testing using the Izod test method for determination of the impact strength and notched impact strength of plastics. Izod impact tests are also described in standards ISO 180 and ASTM D4508. ASTM D256 outlines the Izod impact test for plastics, emphasizing specimen preparation and machine calibration for accurate impact resistance data.

Izod Impact Test (Notched Izod) - ASTM D256 and ISO 180. The Notched Izod Impact Test is a crucial method used to gauge a material's resistance to a swinging pendulum's impact. This singular point test offers a . Discover impact testing methods like Charpy, Izod, and drop weight & learn how they ensure material safety, toughness, and reliability across industries.IMPACT TEST. 1 – Impact properties. The impact properties of polymers are directly related to the overall toughness of the material. Toughness is defined as the ability of the polymer to .Izod impact tests are commonly run at low temperatures - down to -40°F (-40°C) or occasionally lower - to help gauge the impact resistance of plastics used in cold environments.

The Izod notched impact test to ASTM D256 is used on all plastics to characterize the behavior resulting from impact stresses. The flexural impact stress is applied with edgewise impact to a notched specimen that is gripped .

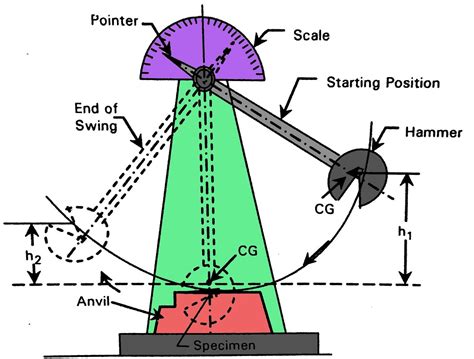

Izod impact tests are commonly run at low temperatures - down to -40°F (-40°C) or occasionally lower - to help gauge the impact resistance of plastics used in cold environments. The impact resistance of a specific commercial grade of .Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.Impact Testing. It is the measure of a material’s resistance to the sudden application of force. Measuring properties like plastic deformation, ductility, and brittleness of materials is essential for proper material selection, ensuring quality control and reliability for finished products.In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

ekg state test hard

Why conduct plastic impact testing?You want your products which are made from plastic to be reliable for their end users and to resist cracking or breaking w.

So, love it or hate it, it appears that the impact test is here to stay. Figure 2. Tinius Olsen's model IT503 enclosed impact tester, capable of performing both Izod and Charpy impact tests on plastic specimens, with up to 25J of available energy with add-on weight sets. Ensuring Repeatable Izod Impact Testing Impact testing is a complex and controversial subject, and one that is in the midst of change. These factors add challenge to selection of the most appropriate impact instrument for a processor's lab. . Of the two basic types of plastics impact testers, pendulum types for Izod, Charpy, and tensile impact measure the energy absorbed by the .The Charpy and the Izod impact tests have a number of differences in addition to their many similarities. One of these variations is the ability to use either metallic or plastic specimens for the Izod impact test. The standard size of plastic samples is a bar with the following dimensions: 64 mm x 12.7 mm x 3.2 mm (V-shaped).The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.

IMPACT TESTING MATTERS, NOW MORE THAN EVER 1.1 What is a Pendulum Impact Test An impact test determines a material’s resistance to an impact event. It measures the amount of energy the material absorbs when it is hit by a high-rate load. The most common impact test methods are Charpy and Izod and are typically run using a pendulum impact tester.

ISO Multipurpose Test Specimen ISO 20753; Izod Impact (Notched) ASTM D256, ISO 180; Izod Impact (Unnotched) ASTM D4812, ISO 180; LM: Lap Shear ASTM D3163, D5868; Lap Shear ASTM D3164; Melt Flow Rate ASTM D1238, D3364, ISO 1133; . Tensile Test Plastics - Microtensile ASTM D1708;The ISO 8256 and ASTM D1822 standards describe the procedure for determining the tensile impact strength of plastics and the performance of tensile impact tests. Tensile impact tests provide a material property based on the impact energy, which is determined under tensile stress on standardized test specimens with a relatively high deformation .This enables us to perform impact tests on a large variety of materials and product forms. Common Standards for Impact Testing. BS EN ISO 180— Plastics. Determination of Izod impact strength; BS ISO 179-1— Plastics -- Determination of Charpy impact properties -- Part 1: Non-instrumented impact test

The resulting test sample measures 80 x 10 x 4 mm. The depth under the notch of the specimen is 8mm. Data: ASTM impact energy is expressed in J/m or ft-lb/in. Impact strength is calculated by dividing impact energy in J (or ft-lb) by the thickness of the specimen. The test result is typically the average of 5 specimens. Impact testing of plastics: present knowledge 213 1881 a falling weight for testing iron and steel. This instrumentation, represented schematically in Fig. 2, was less attractive than the Charpy system because of the difficulties of measuring the energy (using photographs, Dunn7 calibrated springs or copper blocks for arresting the weight). .

These plastic impact test methods measure the energy absorbed by the specimen caused by the impact to create failure. These test are typically pass/fail tests: They give the average impact energy required to break the samples. • The Multiaxial impact test produces a load-deflection curve. Numerous data values related to toughness and total .D1709-24 Standard Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method . Mechanical Properties. D673-93ae1 Test Method for Mar Resistance of Plastics (Withdrawn 1998) D671-93 Standard Test Method for Flexural Fatigue of Plastics by Constant-Amplitude-of-Force (Withdrawn 2002)

Izod impact tester in Blists Hill Victorian Town. The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released.The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated .Simulated Stone Impact Testing is important for new automotive plastic applications including Oil Sumps, Transmision Pans and Cooling System parts exposed to road hazards. . New automotive applications for plastic and composite materials are being introduced which can expose critical components to road hazards and flying debris. Stone impact . Best Equipment for Izod and Charpy Impact Testing. An exemplary tool that stands out for its capability to handle these types of tests is the Class J Impact Testing System. Our system showcases a blend of advanced features and design, making it a top choice for conducting Izod and Charpy impact tests on plastics and rubber specimens.

Here’s what you need to know about some of the best impact-resistant plastics. Best Impact-Resistant Plastics. At SyBridge, we determine a material’s toughness by looking at the results from its Notched IZOD impact test. This test measures the energy absorbed by a plastic, which helps determine how much energy it can stand before deformation.Standards for puncture tests on plastic test plates: ISO 6603-2, ISO 7765-2, ASTM D3763 Test method Objective More information. Jump to the content of the page. English. . In a puncture test, the impact strength of a polymer is determined under increased strain .Scope: Impact tensile strength is the ability to withstand forces due to sudden tensile loading. It is relevant for many industrial applications of plastics such as pipes, electrical insulation on cables, packaging, building construction, and transportation, where components are prone to damage by events such as collision or dropped objects The ASTM D1822 test method [.]

In the case of solid plastics, testing is typically performed by hitting the specimen with a hammer (Charpy or Izod impact tests). For films, a typical impact test is done with the free-falling dart method. Tearing properties of plastic films. The trouser tear test is most commonly used to measure the resistance of plastic films to tearing.Impact Testing most commonly consists of Charpy and IZOD Specimen configurations. specimen types include V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) . A material's toughness is a factor of its ability to absorb energy during plastic deformation. Brittle materials have low toughness as a result of the small amount of .

Izod impact tests are used for characterization of the impact strength of a plastic or composite material at high strain rates. The flexural impact stress is applied to a notched or unnotched specimen gripped on one side, with dimensions 10 x 4 x 80 mm. Tests according to the Izod and Charpy method deliver similar conclusions about the impact strength of a material.

ekg test is hard

what is an impact test

15 de fev. de 2024 · Gestão e Aquisição de. Telecom e TI. A VC-X Sonar é uma plataforma completa que descomplica a automação, aquisição e gestão de telecom e TI para a sua empresa, trazendo visão, controle e .

plastic impact tests|types of impact testing